There are countless unexploited “mines” in every city.

At the Two Sessions (National People’s Congress and the Chinese People’s Political Consultative Conference) this year, many representatives again proposed to build “zero-waste cities”, realize on-site sorting, crushing and reuse of construction wastes to give full play to the role of “urban mines”, and introduce preferential funding policies to support the promotion and application of mature processes and equipment.

At the end of 2018, the General Office of the State Council issued the Pilot Work Plan for the Construction of Zero-waste Cities. In Xi’an, the “Northwest Leading City”, people from all walks of life also proposed to make use of “urban mines” and create a “zero-waste city”.

Many people think that domestic waste accounts for the most enormous volume of the whole waste, but this is not the case. According to calculations by the Ministry of Housing and Urban-Rural Development, for every ton of domestic waste produced, 8 tons of construction waste are produced. The annual production of urban construction waste in China exceeds 2 billion tons, with billions of tons in stock. Construction waste plays a vital role in the garbage siege!

As one of the nine central cities around China, Xi’an has a permanent population of more than 12 million and a population increase of more than 4.48 million in ten years, ranking only second to Shenzhen and Guangzhou.

Xi’an’s urban scale has expanded rapidly in recent years, with unprecedentedly intensive demolition and construction. In the process of demolition and construction, a large amount of construction waste is generated. In the past, construction waste was always piled up in the countryside around the city, which resulted in garbage siege, occupying a large number of land resources and polluting the air and water quality around the dump sites.

In 2018, the Xi’an Municipal Government issued the Implementation Opinions on Strengthening the Resource Utilization of Construction Waste, pointing out that by the end of 2022, the resource utilization rate of construction waste in the urban built-up areas should reach more than 80%.

There are two main ways to reuse and process construction waste: building processing plants and carrying out on-site processing with mobile crushing and screening stations. Although the processing plant has a large processing capacity, it should obtain approval in terms of site selection, construction, environmental protection, etc. It shows a long approval cycle, high cost and transportation expenses, and limited coverage range.

The mobile crushing and screening station can avoid many construction links and reduce transportation costs. It can go wherever needed and become a mobile recycled aggregate processing plant.

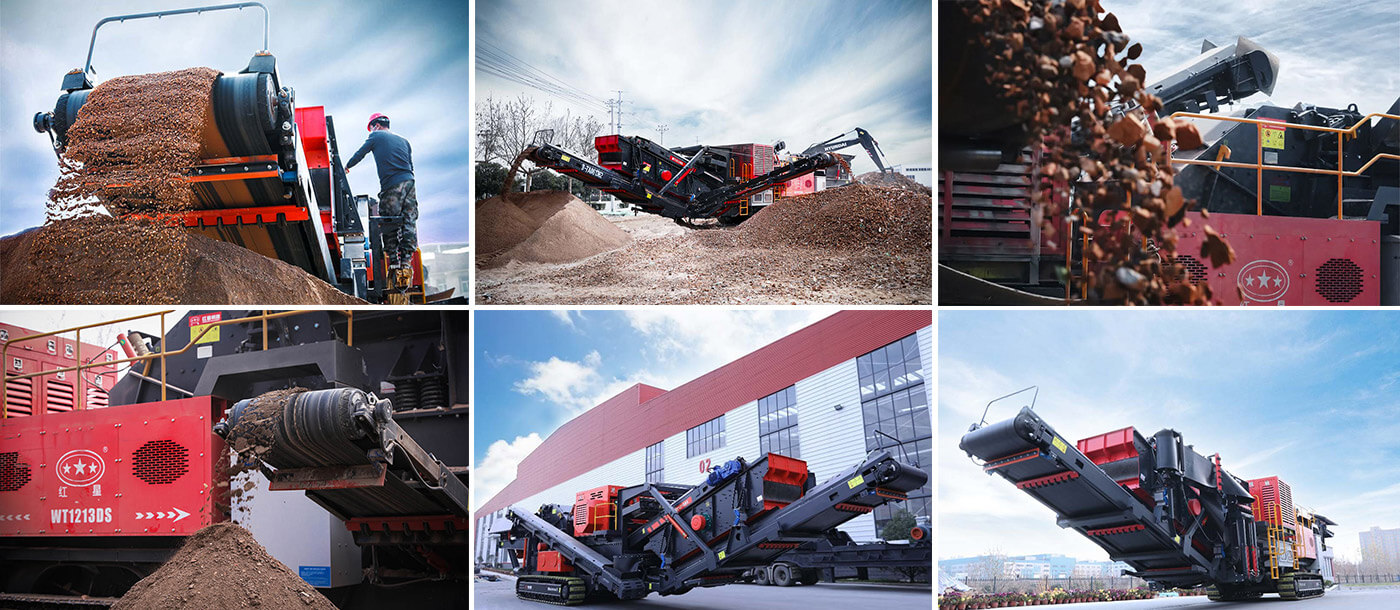

As Xi’an customers’ production plan and equipment provider, Hongxing Group provides customers with customized crawler mobile crushing and screening stations integrating feeder, impact crusher, vibrating screen, power and electronic control modules after comprehensively considering factors such as the production site, material type and output requirements. A station is a recycled aggregate production line.

The recycled aggregate produced has uniform particle size and a wide range of applications, used for the construction of road surface cushion and production of environmentally friendly bricks. The performance advantages of the station, such as crushing, screening, and control, are well received by customers.

The crawler mobile crushing and screening station of Hongxing Group is designed and manufactured with full consideration of different application scenarios, and different configurations will be offered to meet different customer needs.

For example, we provide customers with not only two-deck screening stations (WT1213DS, screening specifications: 0-10mm, 10-50mm) but also three-deck screening stations (WT1213D3S, screening specifications: 0-10mm, 10-20mm, 20-31.5mm).

Screen specifications can also be customized according to customer needs to ensure that aggregates of different specifications screened out can be “fully utilized”.

In general, the crawler mobile station has the following advantages:

Save labor costs

The crawler mobile station, integrating mechanical, hydraulic, electrical and intelligent control technologies, as well as PLC control system, can realize wireless remote control operation, which is convenient and easy to use, greatly saving labor costs.

Reduce transportation costs

The crawler mobile station can carry out production operations immediately when it enters the construction waste site. It is good at climbing operations and will not be restricted by the site. After processing the construction waste in one place, it can quickly transfer to the next place. Without infrastructure, it greatly reduces construction costs and material transportation costs.

Increase aggregate production

The crawler mobile station offers increased output and finer particle size. The output of the station can be adjusted according to customer needs. Product particle sizes less than 10mm can reach more than 80%, while traditional construction waste treatment equipment can only reach 40%, greatly expanding the market of recycled aggregates.

The “zero-waste cities” does not mean that no waste is produced, but that the use of waste, such as construction waste, is maximized. The steel bars in construction waste can be separated and reused with de-ironing separators, and the coarse and fine recycled aggregates produced are of great use. Coarse aggregates can be used for road base courses and “sponge cities” construction. The application scenarios of fine aggregates are more diverse, including the preparation of mortar, as well as the production of concrete and bricks. Many common building materials, such as, blocks, paving bricks, and checkered bricks, are prepared from recycled aggregates. The crawler mobile crushing and screening station can treat all construction waste within the scope of utilization, contributing to the construction of “zero-waste cities”.

In November 2021, the central government proposed in the Opinions on Waging a Determined Battle to Prevent and Control Pollution that we should steadily promote the construction of “zero-waste cities”. In December 2021, the Ministry of Ecology and Environment and other 17 departments jointly issued the Work Plan for the Construction of Zero-waste Cities during the 14th Five-Year Plan Period, proposing to carry out the construction of “zero-waste cities” in about 100 cities and realize the significant improvement of solid waste utilization level and harmless disposal capability by 2025.

Hongxing Group always keeps up with the pace of the times and the national strategies. In the construction of “zero-waste cities”, Hongxing Group provides customers with intelligent and convenient production solutions with innovative technologies and makes contributions to environmental protection with efficient and environmentally friendly equipment, so as to achieve maximum social benefits.