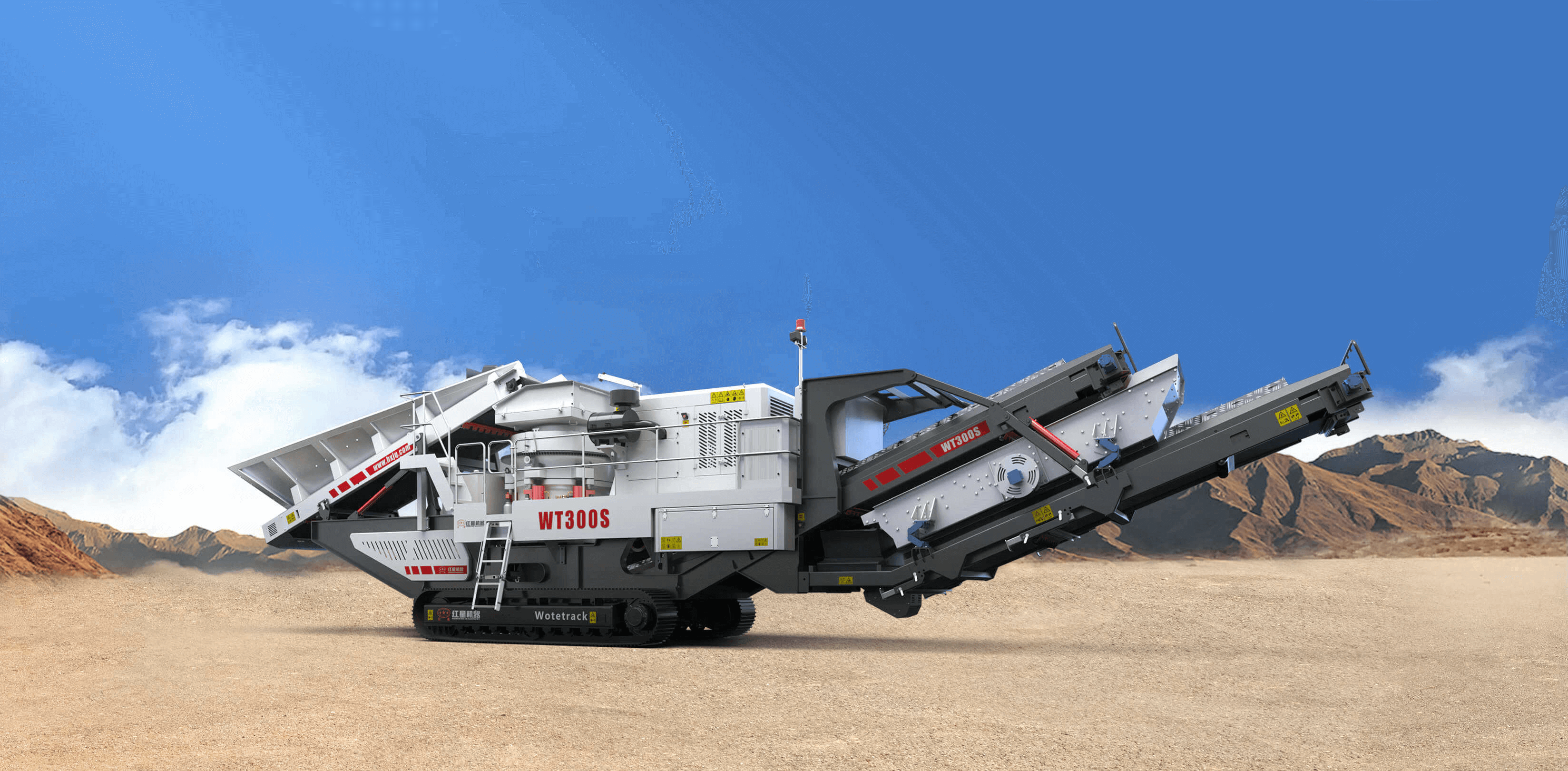

The Wotetrack mobile cone crushing equipment is suitable for processing medium to high hardness, high abrasion natural stone materials, and is also suitable for rough processing of raw materials in mining applications. The conical crushing equipment can ensure the production of finished products with ideal cubic particle shape during the secondary and tertiary crushing stages. The Wotetrack series devices come in different sizes and designs for different purposes. Cone crushing equipment is particularly suitable for use with primary crushing and screening equipment through electrical interlocking.

Product advantages and characteristics

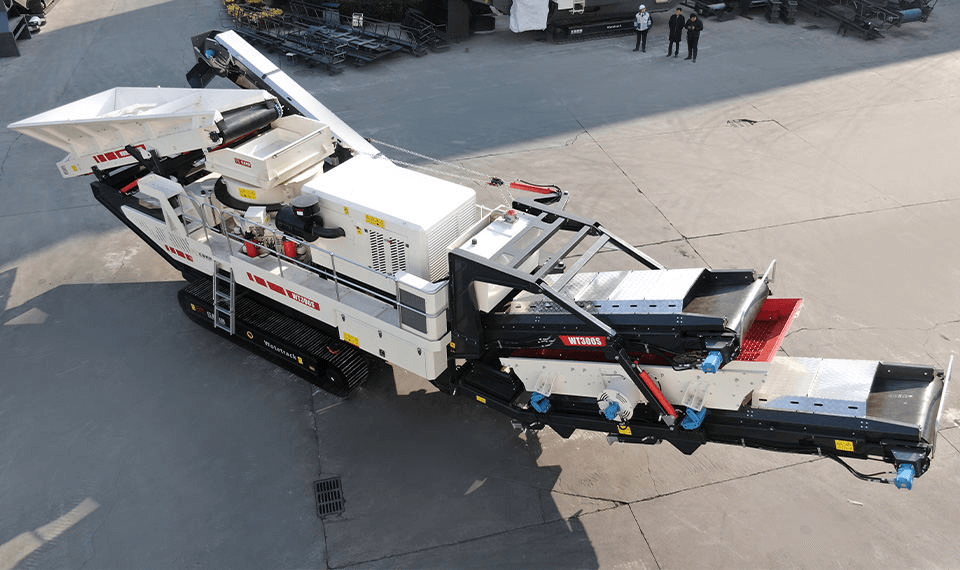

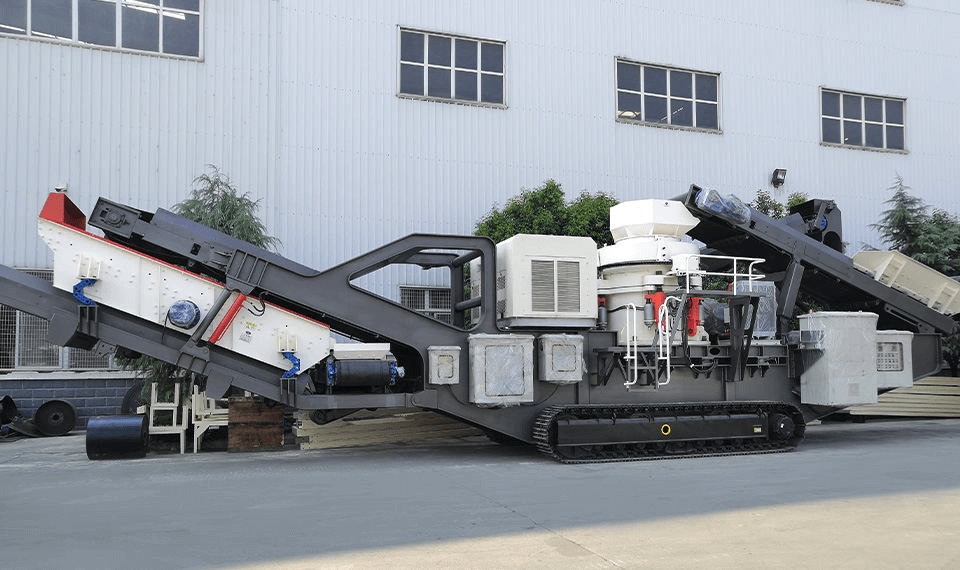

(1) Equipped with a new European version cone crusher, with excellent particle shape and high production capacity.

(2) The constant crushing chamber (CLP) design of the crusher improves the service life of the lining plate, reduces downtime and costs.

(3) User friendly PLC control system and color screen, easy to operate. The diesel engine has a direct drive concept and a low fuel consumption rate.

(4) The material level sensor can adjust the feeding in real-time, optimize the crushing yield and particle shape. Dust suppression devices and dust covers can effectively reduce noise levels, dust emissions, and air pollution.

(5) Optional high capacity single layer vibrating screen and return belt conveyor, flexible and suitable for closed circuit and open circuit crushing operations.

Product Real Shot Display

Device application

Equipment Reference

The crushing of various natural stone materials (limestone, river gravel, granite, basalt, etc.), construction waste (rubble, road concrete, reinforced concrete), coal mining and metal mining industries.