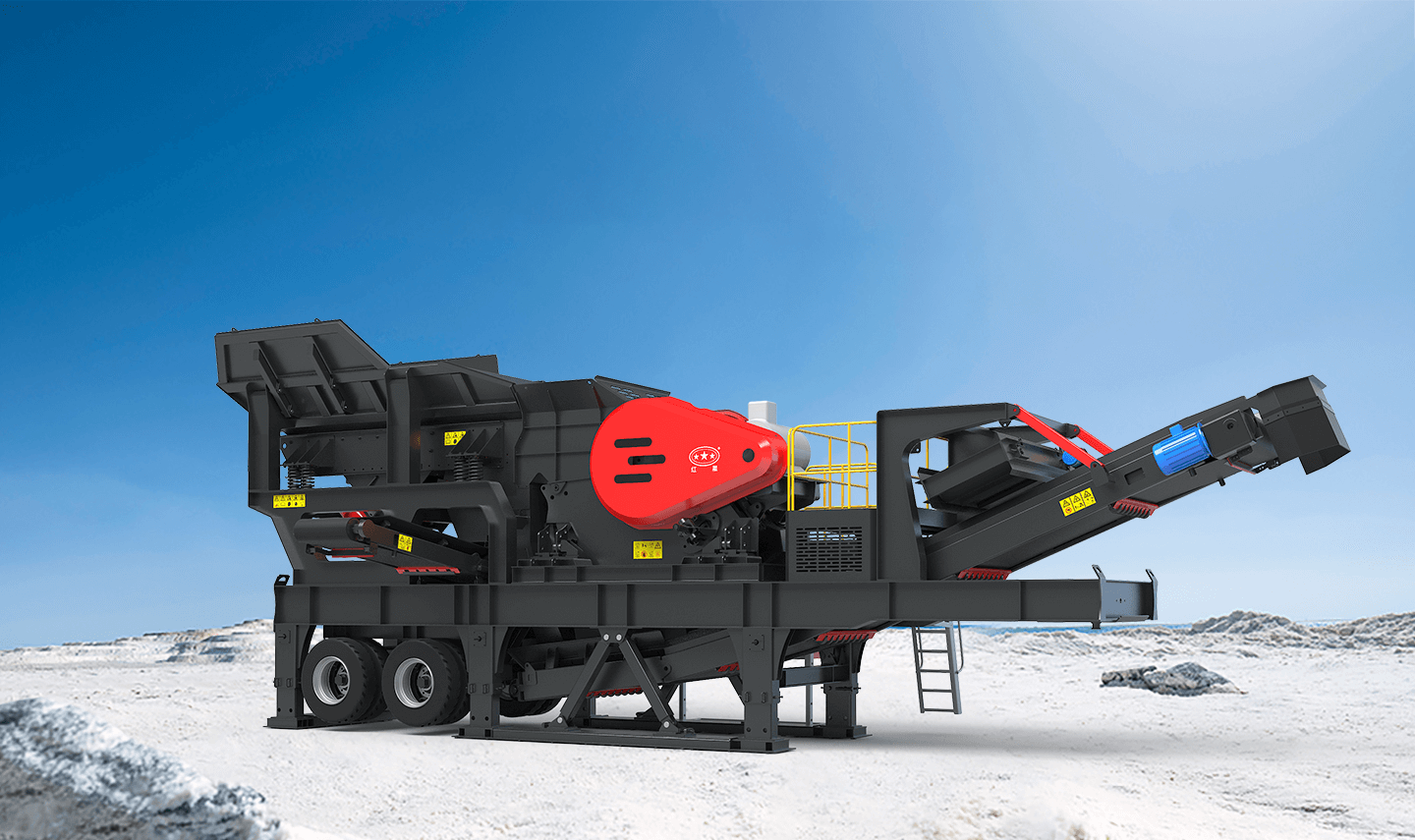

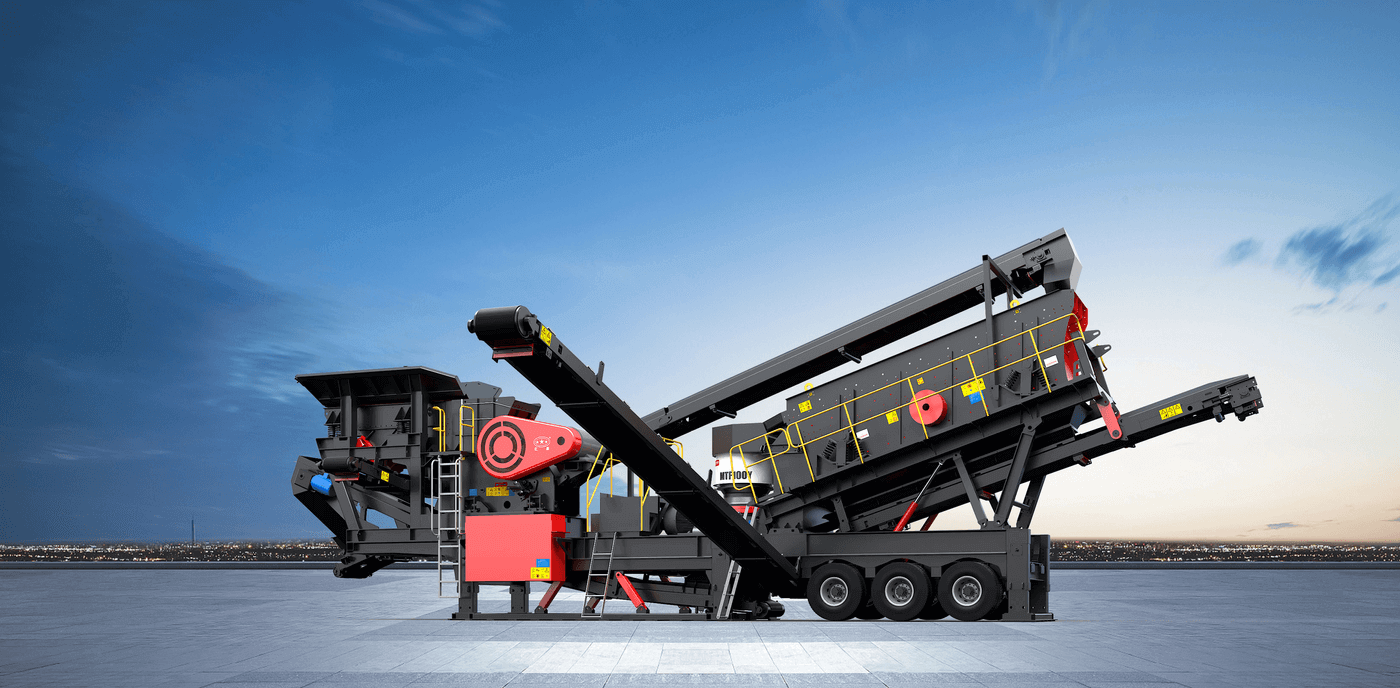

Product Introduction

The MTF series of tire type mobile production lines comprehensively cover the application fields of hard rock, soft rock, and construction waste treatment with processing requirements ranging from 100 to 300 tons per hour. The overall appearance of the mobile station is beautiful, with fine craftsmanship, and equipped with a new technology host. Its performance is stable and reliable, and its output is high. A large number of car mounted belt conveyors, eliminating the need for on-site transportation of external belt conveyors, and ensuring a clean and organized workplace; Each mobile station is equipped with a shoe device to ensure rapid installation and debugging of equipment upon arrival at the site, reducing basic preparation time.

Product advantages and characteristics

(1) High performance host

The host equipment equipped on the production line adopts high-performance hosts produced using new industry technologies, which have high efficiency, high output, few faults, convenient operation and maintenance, and stable and reliable operation.

(2) Modular design

The MTF series mobile production line adopts a modular and universal design, with high structural strength and strong versatility. Equipment with the same processing capacity can achieve maximum versatility, and conversion between different models can be achieved with only a small number of equipment replacement, facilitating mass production, improving production quality, and shortening supply cycles. If there are adjustments to the production materials, rapid production can be achieved by changing the host.

(3) Humanized maintenance and repair platform

The front and rear connectivity design of the maintenance platform facilitates operators to observe the equipment operation and maintain it in a timely manner. The inclined up and down escalator with widened pedals is safer and more convenient than the upright ladder. Some models have added a small ladder at the tail to facilitate personnel inspection and maintenance.

(4) On board electronic control system

Each device on the mobile production line is equipped with an independent electronic control system, which is easy to operate. The cables of each device are connected before leaving the factory, and transportation does not require disassembly. Upon arrival at the site, the entire machine can be quickly debugged.

(5) Vehicle mounted belt conveyor

Each equipment on the mobile production line is equipped with a car mounted belt conveyor, which eliminates the need for disassembly during transportation and saves time for on-site production and installation of external belt conveyors. Upon arrival, work can be carried out quickly, neatly, and in an orderly manner.

(6) Foundation free installation

Each equipment on the mobile production line is equipped with a support leg shoe device, which can save concrete foundation costs and time, reduce the requirements for the workplace foundation, reduce foundation investment, and be folded up during transportation and transfer, allowing for quick support upon arrival at the site.

(7) Design of Large Capacity Storage Bin

The feeding machine silo of the coarse crushing equipment and the feeding belt conveyor silo of the medium crushing equipment are both designed with large capacity, and the side panels of the silo are designed with double layer thickening, which is more sturdy and durable; The large capacity silo is convenient for loading and can store certain materials, ensuring uniform and stable feeding.

(8) Accurately control the feeding amount

The feeder adopts frequency conversion control, which can adjust the feeding amount of the feeder according to different situations, fully leveraging the production capacity of the production line. The feeder is equipped with a pre screening function, which can separate fine materials and slag in advance, improving the equipment’s processing capacity.

Product Real Shot Display