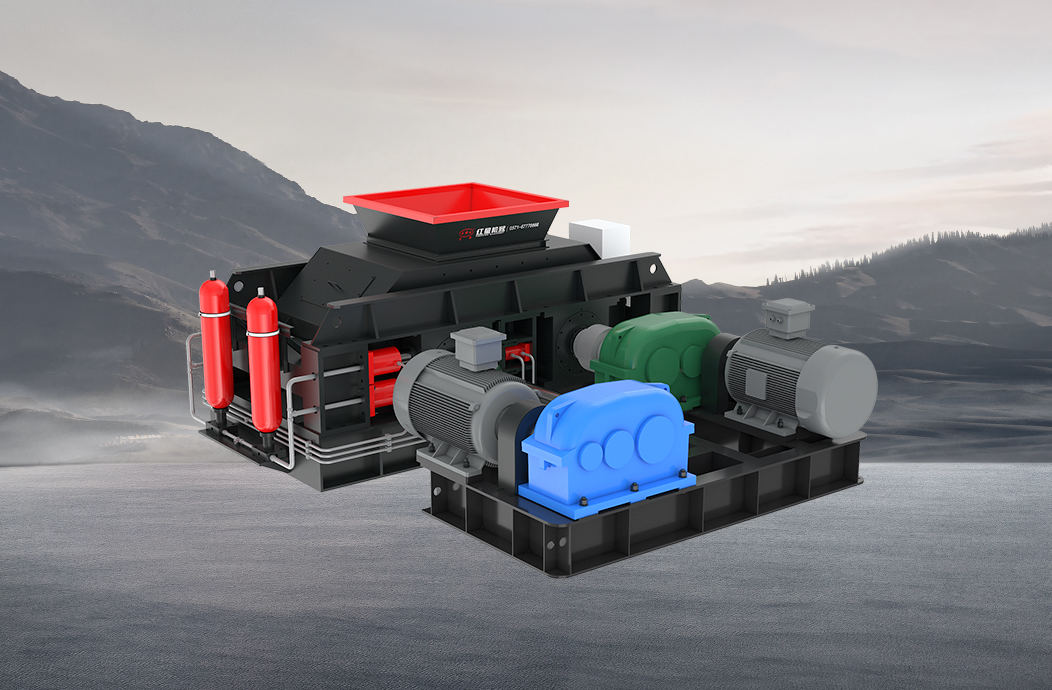

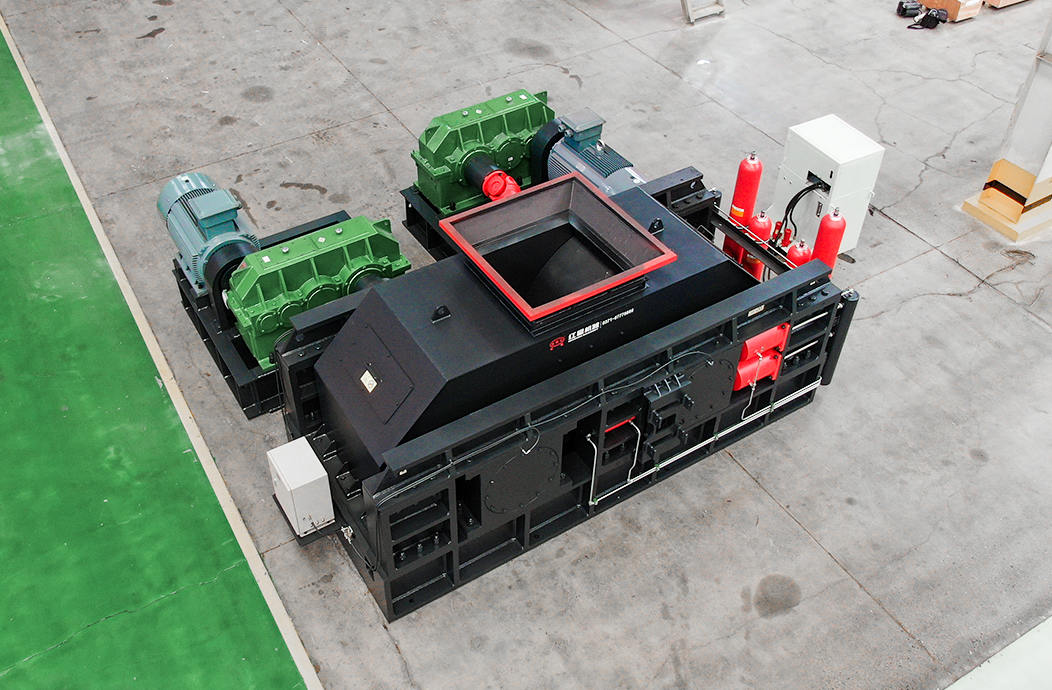

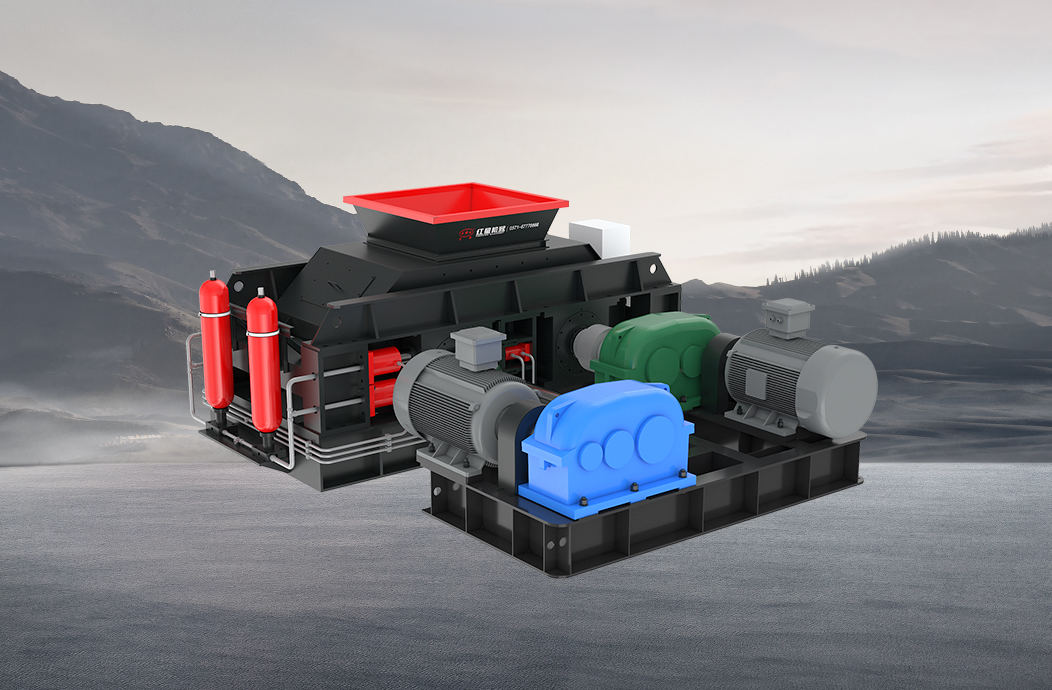

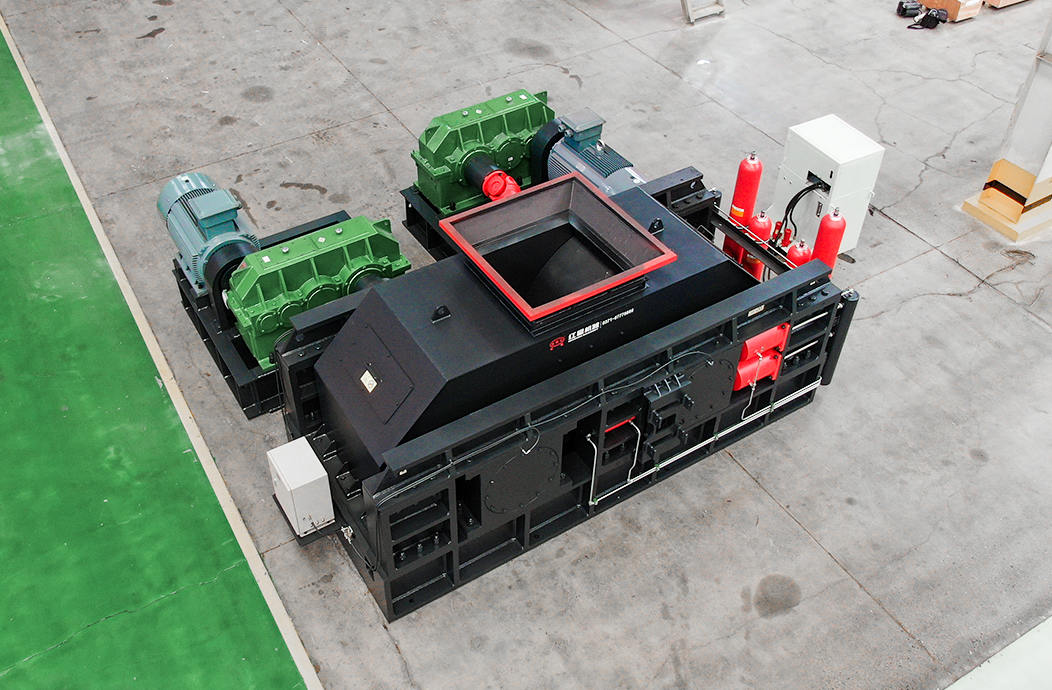

Maximum Feeding Size: 120mm

Capacity: 20-600t/h

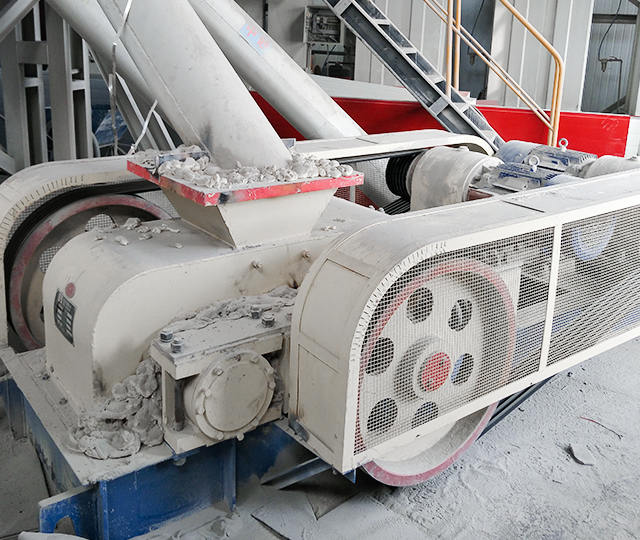

The hydraulic roller mill has an excellent electromechanical and hydraulic integrated design, which enables the equipment to operate continuously, stably and reliably.

It can generally increase the output by 30%-40% and reduce the total energy consumption by 20%-30% in sand and gravel aggregate and grinding systems. It can crush materials of various hardness in the mineral processing, chemical, refractory, stone, building materials and other industries.

Product Advantages and Features

To give you peace of mind

| Model | Roller Diameter (mm) | Roller Width (mm) | Maximum Feed Size(mm) | Corresponding processing capacity of discharge port(t/h) | Power(kw) | ||

| 5mm | 10mm | 15mm | |||||

| 2PGY1008 | ø 1000 | 800 | ≤40 | 20-80 | 30-110 | 50-150 | 2×55 |

| 2PGY1210 | ø 1200 | 1000 | ≤60 | 25-100 | 50-180 | 80-240 | 2×90 |

| 2PGY1510 | ø 1500 | 1000 | ≤80 | 30-130 | 60-240 | 90-330 | 2×160 |

| 2PGY1810 | ø 1800 | 1000 | ≤100 | 40-170 | 80-320 | 120-450 | 2×250 |

| 2PGY2012 | ø 2000 | 1200 | ≤120 | 60-220 | 110-400 | 170-600 | 2×315 |

Note:processing Capacity May Vary With Different Materials And Feeding Sizes.

| Model | Maximum Feed Size(mm) | Corresponding processing capacity of discharge port(t/h) | ||

| 5mm | 10mm | 15mm | ||

| 2PGY1008 | ≤40 | 20-80 | 30-110 | 50-150 |

| 2PGY1210 | ≤60 | 25-100 | 50-180 | 80-240 |

| 2PGY1510 | ≤80 | 30-130 | 60-240 | 90-330 |

| 2PGY1810 | ≤100 | 40-170 | 80-320 | 120-450 |

| 2PGY2012 | ≤120 | 60-220 | 110-400 | 170-600 |

Note:processing Capacity May Vary With Different Materials And Feeding Sizes.

40 years of development

Sold to more than 160 countries

More than 2,300 employees

Covering an area of 500,000 square meters