Maximum feed size: 15mm

Capacity: 3-22t/h

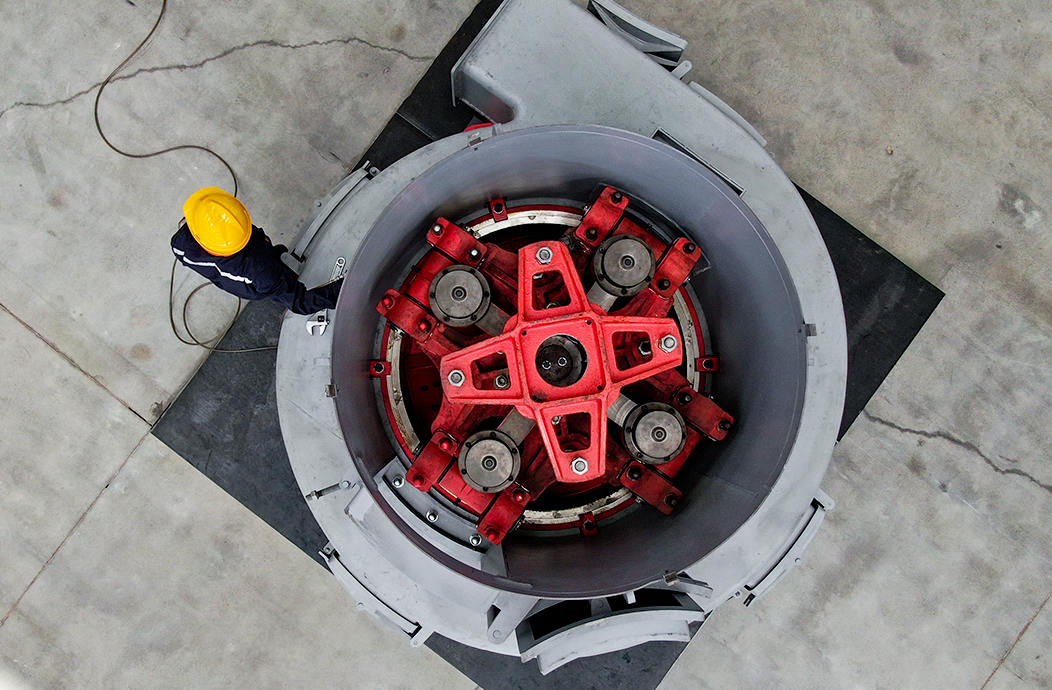

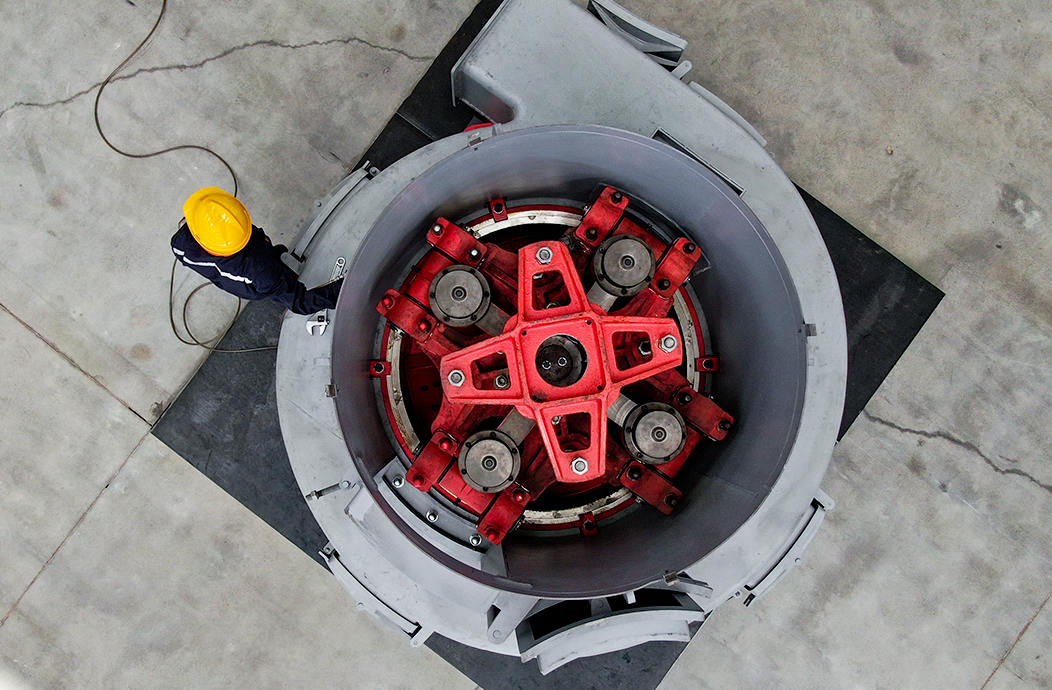

SFLM series ultrafine vertical grinding mill is a large-scale ultrafine vertical grinding equipment suitable for the development requirements of non-metallic mineral industry. It is an ideal equipment for large-scale production of ultrafine powder with high efficiency, high yield, environmental protection and energy saving.

It is widely used in chemical, metallurgical, non-metallic mineral and other industries, and is suitable for the production and processing of ultrafine powder of limestone, calcite, marble, heavy calcium, pyrophyllite, talc and other minerals.

Product Advantages and Features

| Models | Main machine power (kW) |

Powder classifier power (kW) |

Fan Power (kW) |

Grinding material particle size D90 (mm) |

Moisture of grinding material | Capacity (t/h) |

| SFLM1000 | 132-185 | 4×15 | 90-132 | <10(Max15) | <3% | 3-12 |

| SFLM1200 | 220-280 | 6×15 | 185-200 | 4-14 | ||

| SFLM1300 | 315-355 | 7×15 | 200-250 | 5-16 | ||

| SFLM1500 | 355-400 | 8×15 | 280-315 | 7-18 | ||

| SFLM1700 | 450-500 | 9×15 | 315-355 | 8-22 |

Note:processing Capacity May Vary With Different Materials And Feeding Sizes.

| Models | Main machine power (kW) |

Capacity (t/h) |

| SFLM1000 | 132-185 | 3-12 |

| SFLM1200 | 220-280 | 4-14 |

| SFLM1300 | 315-355 | 5-16 |

| SFLM1500 | 355-400 | 7-18 |

| SFLM1700 | 450-500 | 8-22 |

Note:processing Capacity May Vary With Different Materials And Feeding Sizes.

40 years of development

Sold to more than 160 countries

More than 2,300 employees

Covering an area of 500,000 square meters